> Business > Verify

> Business > Verify

Verification of the pcb manufacturing is defined as real opens and shorts of the products or fake.

In order to search fault points after electrical test, ATG-LM CARII software is using in LM digital.

Operating ther system mostly fauity points print out .

In case of ATG LM print out faulty point, barcode of faulty product

operating verify input the barcode no matter how many faulty point printrd , and In shot time input

fault point reduce verify time.

- Open points

Same layer printed as red color and also pointed from start point to end point, it is easy and

useful to find and detecting fault points and if it is necessary inner layer checking is possible too.

Same layer printed as red color and also pointed from start point to end point, it is easy and

useful to find and detecting fault points and if it is necessary inner layer checking is possible too.

- Short point

Short net is printed as different color, so operator can verify short easily without confusing.

Short net is printed as different color, so operator can verify short easily without confusing.

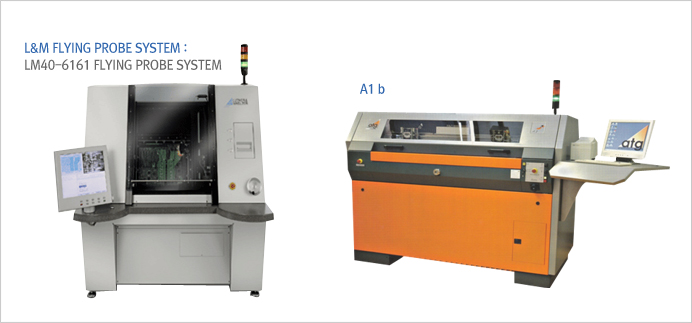

After electrical test, verify of fault points and its points are located in SMD pad and MICRO BGA, small size and highly intergrated products, it is not easy to touch start point to end point using multi-meter lead line. But verify using ATG-LM FLYING PROBE SYSTEM is easy and fast also with accuracy, so mass points of fault verify operating is possible.

In case of ultra- high-density products, ATG-LM can use the output of the testing bad barcode by entering

the coordinates that the defective points can only be retested. It is different other companies.

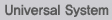

In principle, the system must be tested with universal machine after cheking phantom opens like other PCB product company. But in order to reduce the maximum working hours, the probe system was applied to retest. It can ensure a quick pass process of cheking phantom opens.

In addition, the use of ATG-LM PROBE SYSTEM to complete an electrical inspection showed that it is available for immediate verification which bad product can be quickily finished.